The journey of a Wing Chun practitioner is deeply intertwined with the Mook Yan Jong [1], or Wooden Dummy.

It is more than just a training tool; it is a silent partner, a teacher, and a reflection of the practitioner’s skill and dedication.

For those who choose the path of building their own, the most critical decision, and often the most challenging, is selecting the right wood.

This choice will fundamentally dictate the dummy’s feel, durability, and the quality of the feedback it provides during training.

A poorly chosen material can lead to a dummy that is too light, too soft, or prone to cracking, ultimately hindering your progress.

Conversely, the right wood will create a lifelong training partner that can withstand the rigors of intense practice for decades.

This comprehensive guide will delve into the science and tradition behind wood selection, providing you with the knowledge to make an informed decision for your homemade Wing Chun dummy.

The Core Principles of Wooden Dummy Wood Selection

The purpose of the wooden dummy is to simulate a human opponent, providing a solid, yet responsive, surface for practicing forms, footwork, and trapping hands [2].

Therefore, the ideal wood must possess a specific combination of physical properties to fulfill this role effectively.

The two most important factors are density and hardness.

Density: The Weight of Reality

Density, measured in kilograms per cubic meter (kg/m³) or pounds per cubic foot (lb/ft³), is crucial because it determines the dummy’s overall mass and stability.

A dense wood ensures the dummy has enough weight to remain stable during powerful strikes and movements, forcing the practitioner to develop proper structure and rooting.

As one Reddit user noted, a dense wood is preferable to lighter materials because it has weight, allowing you to feel the load and move it, whereas a light dummy only allows for positional practice [3].

The weight provides a realistic push-back, which is essential for developing the necessary force absorption and redirection skills in Wing Chun.

Hardness: The Measure of Durability

Hardness is typically quantified using the **Janka Hardness Scale**, which measures the force required to embed a steel ball halfway into a piece of wood [4].

A high Janka rating is vital for a wooden dummy, as it indicates the wood’s resistance to denting, scratching, and wear from repeated impact.

Since the dummy will be subjected to thousands of strikes, blocks, and deflections over its lifetime, choosing a hard wood is an investment in longevity.

A softer wood, such as pine, will quickly develop deep dents and grooves, compromising the surface integrity and potentially causing injury or poor training habits.

Traditional and Exotic Woods: The Gold Standard

Historically, the Mook Yan Jong was crafted from woods that were locally available and known for their exceptional strength and durability.

These woods represent the pinnacle of dummy construction, offering a feel and lifespan that is difficult to match.

Teak (Tectona grandis)

Teak is often cited as the traditional wood of choice for the Wing Chun dummy [5].

It is a dense, close-grained hardwood that is highly resistant to rot, decay, and pests, making it incredibly durable.

While traditional Teak (Burmese or Indian) has a respectable Janka hardness of around 1,000 to 1,155 lbf, its true value lies in its stability and resistance to cracking.

However, true Teak is now extremely expensive and often difficult to source in the large, solid logs required for a dummy body.

Cumaru (Brazilian Teak)

Cumaru, often marketed as Brazilian Teak, is a popular modern alternative for high-end dummies.

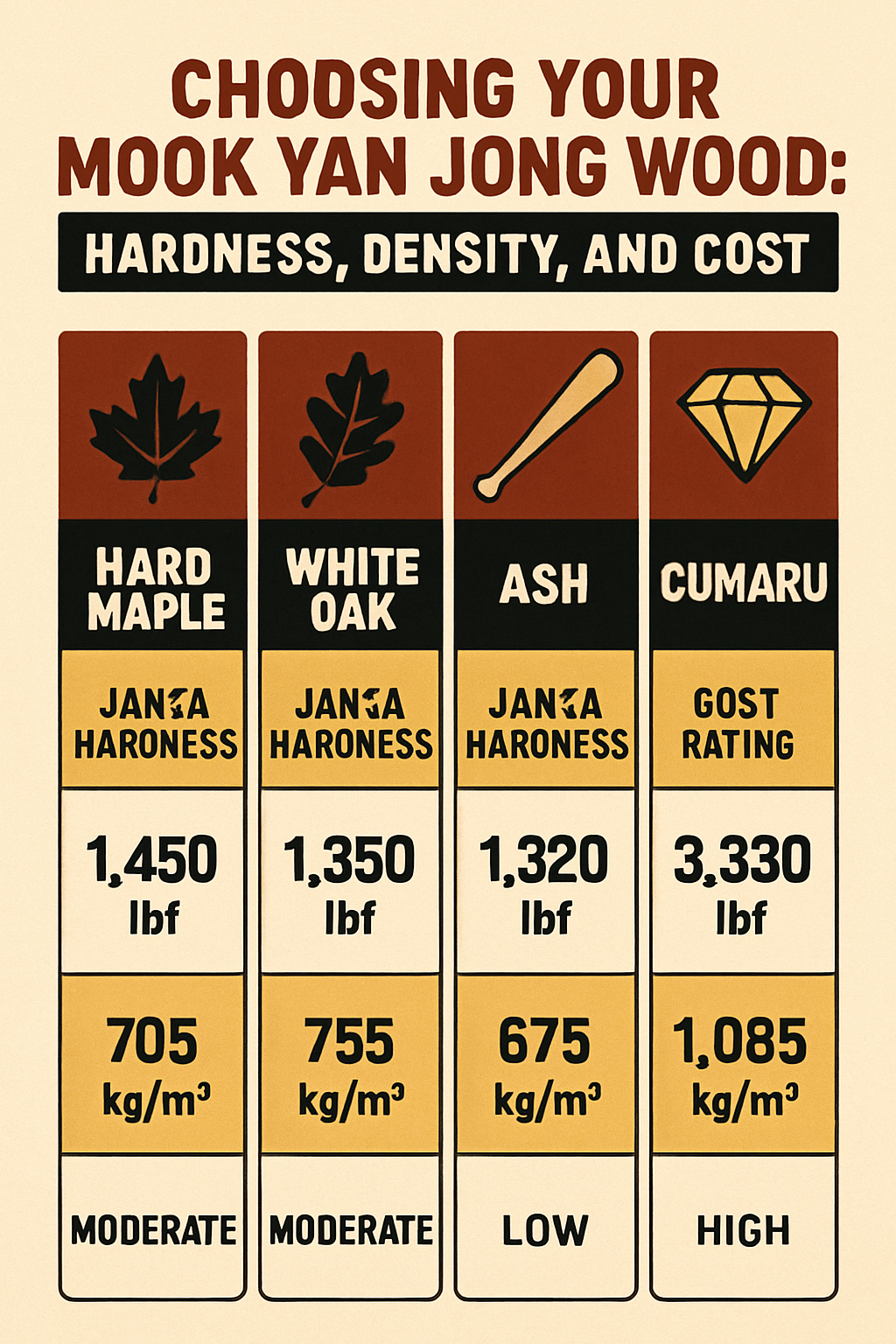

It is significantly harder than traditional Teak, boasting a Janka rating of approximately 3,330 lbf [6].

This extreme hardness makes it virtually impervious to denting from typical Wing Chun strikes.

While an excellent choice for durability, its density and hardness can make it feel less forgiving than traditional woods, and it is also quite costly.

Lychee Wood (Litchi chinensis)

In some lineages, particularly those with roots in Southern China, Lychee wood is revered as the most traditional material.

The wood is incredibly dense and hard, and its natural growth pattern often produces the slight curve needed for the dummy’s trunk.

However, Lychee wood is almost impossible to source outside of its native regions, making it an impractical choice for a homemade dummy project in most parts of the world.

Practical and Affordable Hardwoods for DIY Builders

For the average DIY enthusiast, the exotic woods are often out of reach due to cost and availability.

Fortunately, several domestic hardwoods offer an excellent balance of durability, workability, and cost, making them ideal for a homemade dummy.

Hard Maple (Acer saccharum)

Hard Maple is a top-tier choice for a DIY wooden dummy.

It is widely available, relatively affordable, and possesses a high Janka hardness of around 1,450 lbf [7].

Maple is dense, has a fine, uniform grain, and is highly resistant to abrasion and impact, which is why it is commonly used for bowling alley lanes and butcher blocks.

Its strength and stability make it an ideal material for both the main trunk and the arms.

Oak (Quercus species)

Both Red Oak (approx. 1,290 lbf) and White Oak (approx. 1,360 lbf) are excellent, readily available options.

Oak is a classic hardwood known for its strength and distinctive grain pattern.

White Oak, in particular, is slightly harder and more resistant to moisture, making it a marginally better choice.

While Oak is slightly softer than Maple, it is still more than hard enough to withstand years of rigorous training and is often more budget-friendly than Maple.

Ash (Fraxinus species)

Ash, with a Janka rating of about 1,320 lbf, is another strong contender.

It is known for its excellent shock resistance and elasticity, which is why it is the traditional wood for baseball bats and tool handles.

This slight elasticity can provide a more forgiving, yet still solid, feel that some practitioners prefer, as it mimics the slight give of a human body.

Ash is a great all-around choice that balances performance and cost.

The Construction Debate: Solid Log vs. Laminated Stock

Once you have chosen your wood species, you must decide on the construction method for the main trunk.

This is a critical factor that affects the dummy’s long-term stability and resistance to cracking.

Solid Log Construction

The traditional method involves carving the dummy from a single, solid log.

This method is aesthetically pleasing and maintains the natural feel of the wood.

However, modern solid logs are prone to cracking and warping as they dry and respond to changes in humidity, a process known as “checking” [8].

This is because the moisture content in the log is rarely uniform, and the stresses of drying can cause large, deep cracks that compromise the dummy’s integrity.

Laminated Stock Construction

The modern, and often superior, method is to construct the dummy from laminated stock.

This involves cutting the wood into planks, kiln-drying them to a uniform moisture content, and then gluing them back together using high-strength wood glue, such as Titebond III [9].

Lamination offers several key advantages:

It allows for the use of readily available lumber, which is cheaper and easier to source than a large log.

The process of lamination significantly reduces the risk of cracking and warping, as the opposing grain patterns of the glued planks counteract internal stresses.

The resulting dummy is often stronger and more stable than a solid log, as modern wood glues are often stronger than the wood itself.

For a homemade dummy, laminated construction is the most practical and reliable approach.

Wood Comparison Table: Hardness, Density, and Cost

To help you visualize the differences between the top contenders, the table below compares the key metrics for the most common and recommended Wing Chun dummy woods.

| Wood Species | Janka Hardness (lbf) | Density (kg/m³) | Cost & Availability | Best For |

|---|---|---|---|---|

| Cumaru (Brazilian Teak) | ~3,330 | ~1,080 | Very High Cost, Low Availability | Ultimate Durability, Professional Grade |

| Hard Maple | ~1,450 | ~700 | Moderate Cost, High Availability | Best All-Around DIY Choice |

| White Oak | ~1,360 | ~770 | Moderate Cost, High Availability | Excellent Density, Good Durability |

| Ash | ~1,320 | ~710 | Moderate Cost, High Availability | Good Shock Absorption, Forgiving Feel |

| Teak (Traditional) | ~1,155 | ~740 | Very High Cost, Low Availability | Traditional Feel, High Stability |

| Pine (Softwood) | ~400 | ~500 | Low Cost, Very High Availability | Temporary/Starter Dummy Only |

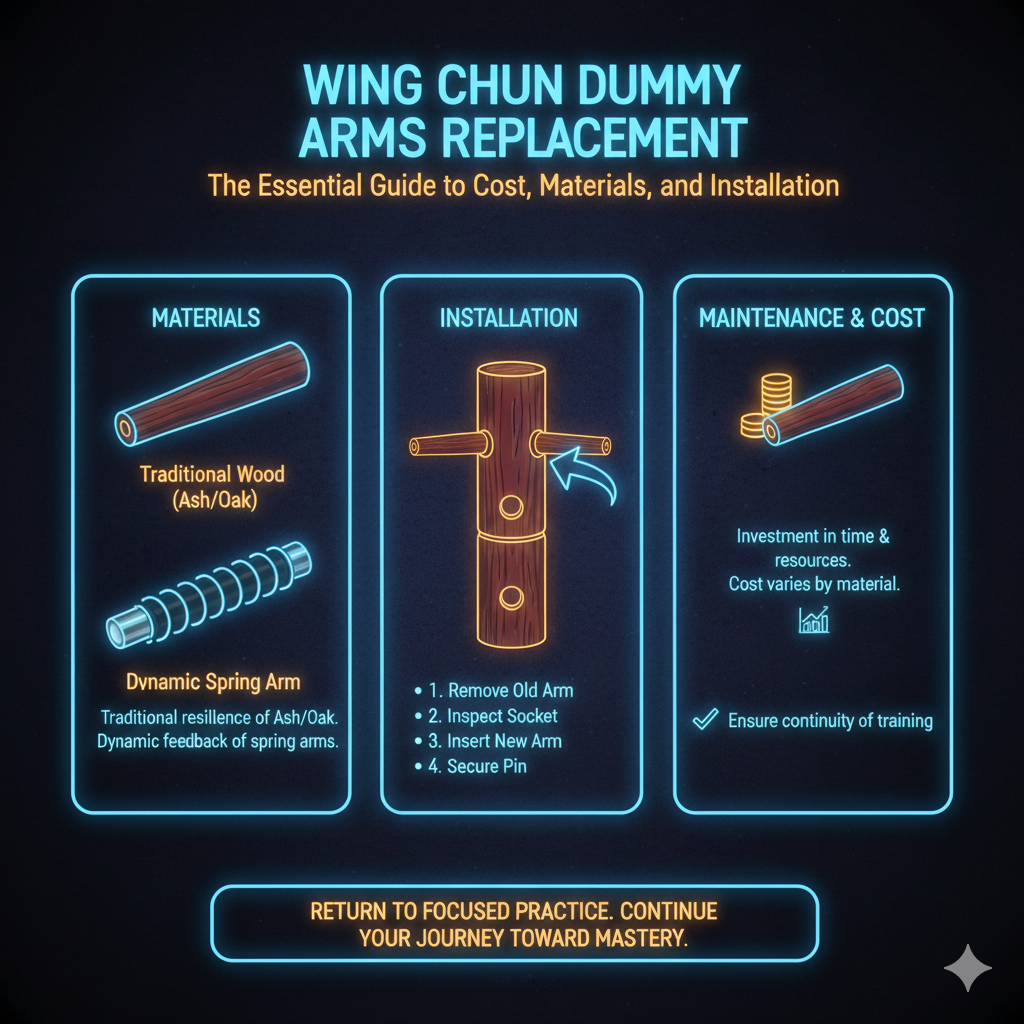

Beyond the Trunk: Choosing Wood for

the Arms and Leg

While the main trunk is the heart of the dummy, the arms and leg are the most frequently struck components, and their wood selection is equally important.

The arms and leg should ideally be made from the same wood as the trunk to ensure a consistent feel and response, but there are other considerations.

The Arms: Flexibility and Resilience

The three arms of the Mook Yan Jong are designed to simulate the limbs of an opponent.

They must be strong enough to withstand direct impact but also possess a degree of resilience to avoid snapping.

For the arms, a wood with good **Modulus of Rupture** (MOR) and **Elastic Modulus** (MOE) is beneficial, as these metrics relate to the wood’s bending strength and stiffness [10].

Hard Maple and Ash are particularly well-suited for the arms due to their excellent combination of hardness and shock resistance.

If you are using a very hard wood like Cumaru for the trunk, using a slightly less brittle, high-strength wood for the arms can be a wise choice to prevent premature cracking at the joints.

The Leg: The Foundation of Footwork

The leg is crucial for practicing low-line techniques and developing proper footwork and structure.

It must be incredibly strong, especially at the joint where it meets the trunk.

The same principles apply here: a dense, hard wood will ensure the leg does not splinter or break under the torque and impact of powerful kicks and sweeps.

Laminated construction is also highly recommended for the leg, as it can be engineered to be stronger than a single piece of wood with a potential weak point.

The Case Against Softwoods and Alternatives

While the temptation to use readily available and inexpensive softwoods like Pine or Spruce is strong, it is a decision that will likely lead to regret.

Pine, for example, has a Janka hardness of only about 400 lbf, making it extremely soft for a martial arts training tool.

It will quickly become pitted and damaged, requiring constant repair or replacement.

This compromises the smooth surface needed for proper sliding and contact drills.

Similarly, alternatives like PVC pipe, while cheap and easy to assemble, lack the necessary weight and density to provide realistic feedback, turning the dummy into a mere positioning guide rather than a structural training partner.

The investment in a quality hardwood is an investment in the integrity of your training.

Final Considerations for Your DIY Project

Before you begin cutting, there are a few final factors to consider that will influence your wood choice and construction process.

Moisture Content and Seasoning

Regardless of the wood you choose, ensure it is properly seasoned and has a low moisture content (ideally 6-8% for indoor use).

Using wood that is too “green” (high moisture content) is the primary cause of cracking and warping, especially in solid logs.

If you are using lumber, purchase kiln-dried stock from a reputable supplier.

Sourcing and Budget

Your local lumberyard is your best resource.

Call ahead to check the availability and price of Hard Maple, White Oak, and Ash.

These woods are often sold as rough-sawn lumber, which will require milling, or as pre-milled planks, which are easier to work with for lamination.

Set a realistic budget, understanding that the wood will be the most significant expense of your project.

Finishing the Dummy

Once constructed, the dummy should be finished with a light coat of oil or wax, or left completely unfinished.

Avoid heavy varnishes or polyurethane, as they create a slick, unnatural surface that can interfere with the development of proper contact sensitivity (Chi Sao).

A simple coat of boiled linseed oil or a natural wood wax will protect the wood while maintaining a natural, tactile feel.

Conclusion: The Partner You Choose

Choosing the right wood for your homemade Wing Chun dummy is a decision that should be made with careful consideration of tradition, physics, and practicality.

While the exotic woods like Cumaru and Teak offer unparalleled durability, the readily available and high-performing domestic hardwoods—Hard Maple, White Oak, and Ash—are the most sensible and effective choices for the DIY builder.

By prioritizing density for weight and hardness for longevity, you will create a Mook Yan Jong that not only stands the test of time but also enhances the quality and depth of your Wing Chun training.

The effort you put into selecting the perfect wood will be repaid tenfold in the quality of your practice.

This video shows a good process for making a basic wooden dummy, which can be adapted for your chosen hardwood.

A look at a high-end Cumaru dummy, demonstrating the finished product of a very hard wood.

An unboxing and review of a solid wood dummy, providing context on what a quality dummy should look and feel like.

Further Reading and Resources

For those looking to deepen their understanding of the Mook Yan Jong and its construction, here are some high-authority external resources:

- The Dragon Institute: How to Build a Wooden Dummy (w/ Plans & FAQs). This article provides excellent context on the dummy’s role and construction.

- The Wood Database: Cumaru (Brazilian Teak). A detailed technical breakdown of one of the hardest woods used for dummies.

- Bell Forest Products: Janka Hardness Chart. A comprehensive list for comparing the hardness of various wood species.

- Engineering ToolBox: Density of Wood Species. A technical resource for comparing the density of different woods.

- iLoveWingChun: